Mar 13, 2025 Artificial Intelligence

AI in Manufacturing: Use Cases and Real-Life Examples

Mar 13, 2025 Artificial Intelligence

Table of Contents

Mar 13, 2025 Artificial Intelligence

Using AI in manufacturing has become a hot topic among factory owners and manufacturers! As AI is gradually being implemented in almost every aspect of our lives, it has raised as many questions and doubts as it has answered!

Isn’t it?

But the ultimate answers to the questions concerning “AI in Manufacturing” depend upon how AI technology is defined and used by manufacturers. So, the executives in manufacturing and industrial companies looking to implement AI in their organization and automate the process but not sure where to start and how to proceed should consider this blog.

By the end of this guide, you will learn how the right people, automated processes, and organizational structure can help you succeed with AI-driven innovation and mindful integration.

From Digital Novices to Digital Leaders: How AI is Transforming the Manufacturing Industry?

Earlier, “AI in Manufacturing” was something more of a future dream, but now it’s a reality that is reshaping the manufacturing industry at a fast pace.

For manufacturers, AI promises to be a game-changer at every level of the value chain. From direct automation to predictive maintenance and reducing operational costs to ensuring 24/7 support and quality control- there are a number of rewards for embracing the transformation and mastering the implementation of AI throughout the entire business.

However, if you are one of those who haven’t witnessed much growth with the adoption of AI in manufacturing, then the good news is that it’s not too late to start over again!

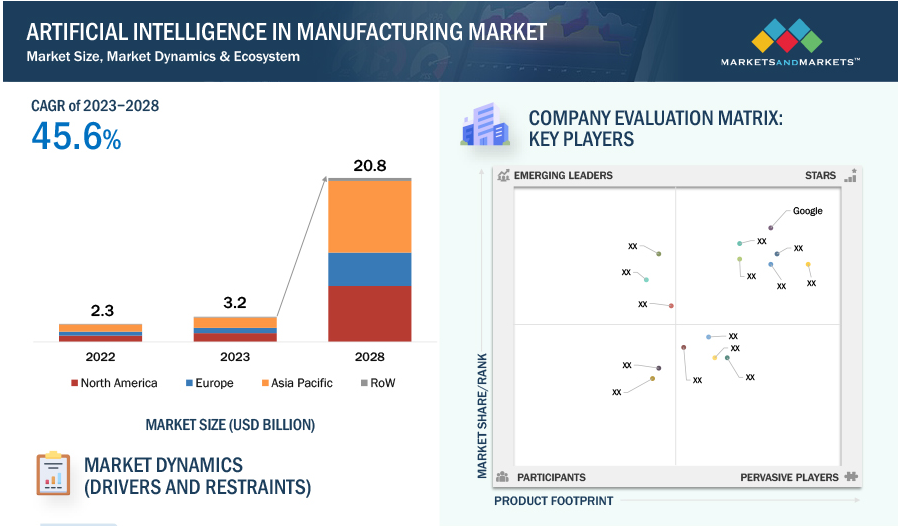

Still, if you are in a dilemma about whether it be a worthy decision to rethink or get started with AI implementation in manufacturing, then you should take a sneak peek at these market stats.

Investing in digital transformation can be a budget and effort-draining decision for many factories or manufacturers. But with these eye-opening stats, surely you will be aligned with the fact that embracing AI is the new normal in manufacturing.

Here are some stats portraying the progressive picture of using AI in Manufacturing:

With such figures, it’s quite obvious that AI is becoming the most preferable choice for manufacturers.

With this industrial revolution and leveraging the various types of AI’s assisted intelligence, augmented intelligence, autonomous intelligence, and automation, factories have been rapidly and inexpensively producing products to satisfy the increasing demand.

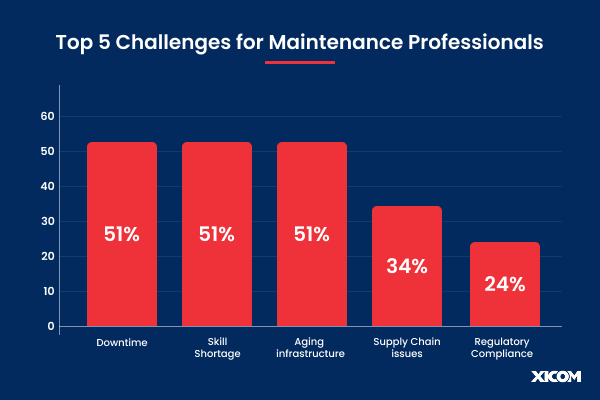

But as they are quickly paving their way towards this digital transformation, they are confronting a wave of new challenges, including:

In addition, manufacturers are still contending with the problems they have always faced, such as higher production costs, equipment failure, and bottlenecks in the supply chains.

Now, here is the catch. Just implementing AI in manufacturing won’t work. You need to hire an AI app development company that will take a deep look into your requirements and customize the strategy to drive the desired results.

If you are seeking the tools to automate and revolutionize operations and procedures in your manufacturing company by implementing AI, then let’s learn how AI affects manufacturing companies and how businesses can attain excellent success through it.

With AI revolutionizing manufacturing, everyone is asking the same question: How, exactly, does it make a difference? For companies just beginning to leverage AI, knowing the most important use cases will help them understand the enormous improvements and greater success they can anticipate.

Here are the top 12 use cases along with AI in manufacturing examples:

The supply chain is one of the most integral parts of manufacturing and poor handling of supply chain disruption could result in a loss of $1.5 trillion in value.

This is where AI has been growing significantly in shaping the future of the global economy and encouraging companies to harness transformative technology to stay ahead in the rapidly evolving industry.

It is predicted that AI is all set to revolutionize the manufacturing businesses operating and delivering value. In 2025, AI technologies are expected to contribute a staggering $5 trillion in economic value and provide a strategic tool to organizations to have a competitive advantage.

Let’s understand how using AI in Manufacturing to streamline supply chain management makes more sense…

In 2024, the US manufacturing sector faced weaker demand with PMI shifting between expansion and contraction, where orders were falling and customer inventories were rising. This alarming situation was constantly signaling manufacturers to further cut production in the coming month. However, with the lack of clear visibility in supply chain management, manufacturers continue to face higher costs.

Role of AI – AI-powered predictive analytics can help manufacturers to evaluate demand fluctuations, enable them to adjust product levels, and optimize the entire inventory management in demand.

By bringing AI into use, Amazon enhanced demand prediction and supply chain resilience, further resulting in cost reduction and enhanced customer satisfaction.

Earlier in 2020, Amazon saved $1.6 billion using AI and Machine Learning in manufacturing. Amazon also utilized AI systems to forecast demand for over 400 million products on Cyber Monday Sales during 2023 to predict where the orders were coming from based on their historical data. AI has made the supply chain of Amazon go 75% faster.

While talking about the manufacturing industry, making sure that its machinery and equipment are running smoothly is the biggest concern for the executives.

The sudden equipment failures not only cause unexpected production delays but also result in a $1 trillion loss annually.

Whereas, in the automotive sector, plants lose 29 production hours a month, on average which costs around $1.3 million per hour, resulting in $557 billion of loss per hour.

This is where AI in manufacturing takes charge and turns out as a game-changer decision. It has a significant impact in revolutionizing maintenance by forecasted equipment failures based on analyzing real-time sensor data.

Here’s how it works:

The integration of AI allows dynamic scheduling based on the actual equipment condition, reducing unnecessary maintenance and downtime. These AI models keep updating themselves to ensure adaptability to changing conditions. To make these models work rightly, manufacturing companies need to hire app developers to create customized apps that align with their specific challenges.

ZF Friedrichshafen AG, is a global leader in the automotive manufacturing industry, leveraging AI-driven predictive maintenance to enhance efficiency and reduce unplanned downtime in its Saarbrucken Plant.

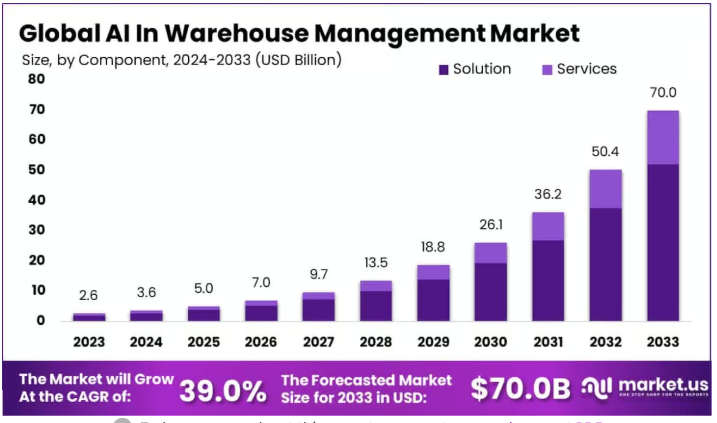

By using smart technologies, manufacturing units can significantly improve accuracy and minimize operational costs. Inventory Management is one of the major applications of AI in warehouse management processes. AI algorithms can leverage past sales data, current stock levels, and market trends to predict demand patterns with high accuracy.

With this approach, warehouses can easily optimize inventory levels effectively, reducing carrying costs while ensuring consistent product availability. With an accurate demand prediction, warehouses can maintain optimal stock levels, ultimately reducing both stockouts and overstocking. With the needful stocks, businesses can improve customer satisfaction while having full-fledged control of financial spending.

As per the reports, the Global AI in Warehouse Management market is expected to be worth around USD 70 billion by 2033, from USD 2.6 billion in 2023, growing at a CAGR of 39.0% during the forecast period from 2024 to 2033.

Ocado has transformed warehouse management by integrating AI solutions for dynamic inventory management. Real-time tracking ensures that items are stored in optimal locations for quick retrieval. The solution’s capabilities learn and fetch data from order patterns to predict demand and adjust storage accordingly.

For instance, all the high-demand items are stored closer to the surface to reduce the peak-hour retrieval times.

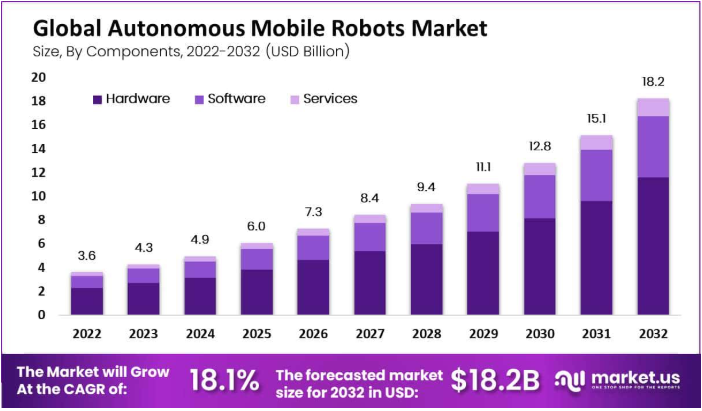

Collaborative Robots, also known as Cobots, are becoming one of the major choices of AI solutions for manufacturing. With cobots in use, manufacturers can increase productivity by collaborating with human operators. Generally, these robotic machines are seen at the fulfillment centers as pickup and pack helpers assisting humans.

Traditional industrial robots are often isolated from humans due to safety concerns, whereas the Cobots are designed to ensure a safe environment for humans. These AI solutions for manufacturing navigate intricate areas and identify objects.

This AI-influenced sector is expected to maintain a consistent annual growth rate. A compound annual growth rate (CAGR) of 3.83% is projected from 2023 to 2028. With this, the market size is expected to reach approximately 45.09 billion by 2028.

Example: Ford

Ford is the leading automobile manufacturing company leveraging Cobots to enhance manufacturing efficiency and quality. These robotic assistants can be used to perform tasks like sanding car bodies and assisting in assembly lines, reducing worker strain and improving precision. It might fascinate you to know that in Germany, six UR10 cobots sand a Ford Fiesta’s body in just 35 seconds.

Among all the other AI in manufacturing examples, Cobots have some major significance in developing efficiency improvement, worker safety and comfort, quality enhancement, and flexibility with robotic assistance.

AI in manufacturing leverages the latest and upgraded technologies to optimize the assembly line process. AI capabilities like machine learning, computer vision, and digital twins help enhance efficiency by predicting equipment failures, automating quality control, and simulating production scenarios.

In addition to this, costs can be reduced by ensuring minimum failure with AI predictions. Manufacturing companies can boost productivity, save costs, and enhance quality, improving overall manufacturing performance.

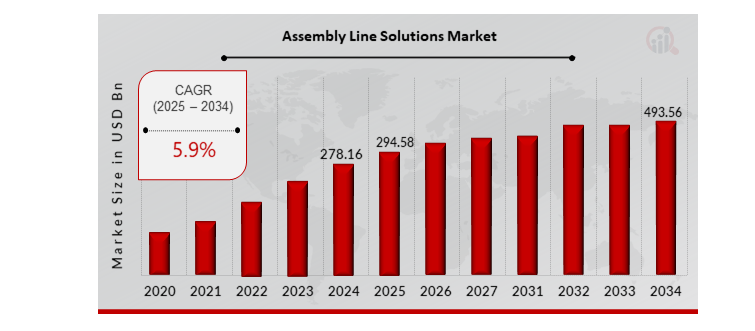

The market size of Assembly Line Solutions was valued at USD 278.16 billion in 2024. By 2025, it is expected to grow from USD 294.58 billion to USD 493.56 billion by 2034. This growth rate exhibits a CAGR of 5.9% during the forecast period.

Example: BMW

BMW Group, the leader in the automotive industry, has been strategically leveraging AI in its vehicle assembly process. This approach has increased production efficiency, accuracy, and quality, significantly reducing the time to market for the new models. BMW’s AI innovations like Car2X and AIQX are amongst the major achievements.

AI innovation Car2X enables real-time communication and interaction between vehicles and the production system during the assembly. This AI solution for manufacturing has been the game-changer, saving BMW over $1 million annually and eliminating the need for six assembly line workers.

With the introduction of AI in the manufacturing industry, a significant development of new products has been witnessed. Manufacturing companies have restructured the ways to create and introduce new products to the market with the innovative approaches that AI has brought.

AI solutions in manufacturing for new product development are beneficial in analyzing vast amounts of data quickly and efficiently.

By leveraging the features of Machine Learning in manufacturing, firms can gather insights to make data-driven decisions and design products that accurately align with market demands. ML helps organizations to identify areas of failure, predict potential issues in new designs, and propose better designs for the new product.

Another major example of AI applications in manufacturing is Generative design software for the development of new products. This employs Generative AI for accelerating the overall design iteration process, making way for optimized and innovative product designs. These applications of AI boost the speed of creating new products by allowing for rapid exploration of design alternatives based on the business requirement.

Example: NVIDIA

NVIDIA, the leading company in chip manufacturing, leverages Machine Learning development services for assessing large datasets on component architectures that make it possible to foresee issues with the upcoming chip designs and identify possible failure points.

With AI-based analytics, manufacturing software can increase the speed time to market, optimize semiconductor layouts, cut down expenses, and increase yields.

It’s quite important for manufacturing companies to optimize performance. AI for manufacturing companies can streamline the performance optimization process. It helps in identifying patterns and data anomalies and makes data-driven predictions by analyzing historical data, real-time sensor data, and various other relevant factors.

This approach can enable manufacturers to optimize operations and minimize downtime while maximizing the overall effectiveness of the equipment.

Example: GE

General Electric (GE) integrates AI algorithms into its manufacturing processes for analyzing vast data from sensors and historical records. With this approach, GE easily identifies trends, predicts equipment issues, and streamlines operations.

Predictive Maintenance here reduces downtime and costs by addressing issues early. In addition to this, Digital Twins simulate equipment performance, optimizing operations and enhancing efficiency. As per the reports, GE developed over 1.2 million digital twins, which generated approximately $600 billion in value for the company and its customers.

Manufacturing industries use AI to implement quality control, greater accuracy, and uniformity. Applications of Artificial Intelligence in manufacturing can be made to utilize computer vision algorithms to analyze product or component images or videos. Furthermore, it becomes simpler to correctly detect defects, anomalies, and deviations in quality standards than in human ability.

Example: Ford

Ford utilizes AI-driven computer vision to enhance quality control. AI systems can quickly analyze images to detect imperfections that human inspectors might miss. This approach helps in improving accuracy and product quality.

With AI in use, Ford has enhanced its reliability, reputation and financial performance by minimizing defects and optimizing manufacturing processes.

Manufacturing firms mainly play around paperwork like purchase orders, SOPs, and reports. The documents were handled through the traditional manual process earlier, which consumed a lot of time and was prone to errors. Moreover, the traditional process introduced inefficiencies and delays. Robotic Process Automation (RPA) is possible with AI and ML in manufacturing.

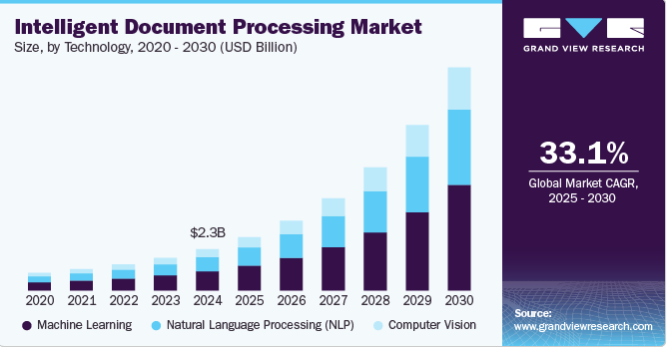

The global intelligent document processing market size was estimated at USD 2.30 billion in 2024 and is projected to grow at a CAGR of 33.1% from 2025 to 2030.

To automate these paperwork processes, organizations can implement conversational AI in manufacturing. Businesses can also employ smart bots for automatically extracting data from documents, classifying and categorizing information to integrate it into appropriate systems. It helps in streamlining and enhancing the accuracy of the paperwork.

Example: Whirlpool

Whirlpool leverages Robotic Process Automation for automating its manufacturing processes, specifically on the assembly line and material handling tasks. These RPA automate repetitive rule-based tasks, ensuring accuracy and productivity in the manufacturing process. This approach helps Whirlpool streamline operations and maintain a high standard of product quality.

AI can be a huge help in forecasting demand for the manufacturing sector. Companies that employ AI-based applications for manufacturing can make rational decisions by observing the previous market trends and sales records. It helps forecast the change in demand to initiate production accordingly to prevent stock out and overstock.

For example, clothing industry companies can avail the predictive functionality of AI utilizing data from an assortment of origins such as the trend on social media and sales demand. A store can prepare beforehand by utilizing suitable predictions so they can meet the required demands for production.

Example: Zara

Popular clothing brand Zara uses AI algorithms to identify patterns and predict what fashion trends will be in vogue in the future. AI in the manufacturing industry, especially for cloth producers, can handle data efficiently for product production, inventory management strategy, and marketing campaigns.

Through this strategy, Zara can stay ahead of its rivals by embracing the latest and prevailing fashion trends.

Artificial Intelligence in manufacturing simplifies and streamlines the entire process of order fulfillment. Through Machine Learning algorithms, manufacturers can process historical data, customer preferences, and market trends for demand forecasting. This allows for the automation of orders, thereby removing errors and improving efficiency. Apart from this, AI can enhance fraud detection, reducing the risk of counterfeit orders.

AI manufacturing solutions automate the whole order management process by accelerating op decision-making and delivering a more responsive and customer-centric approach.

Example: IBM Waston

One real-life AI in manufacturing example for order management is IBM Sterling Order and Fulfillment suite, which uses generative AI and Machine Learning to maintain order accuracy and profitability.

The entire suite encompasses pre-configured applications and modular solutions that amplify buying experiences, simplify buying processes, improve supply chain resiliency, and equip front-line workers with enhanced inventory and order management features.

As opposed to standard factories, wherein machinery and systems are isolated from one another, connected factories engage with sophisticated technology to enhance their manufacturing processes. It brings together systems such as machinery, robots, IoT equipment, and analytics driven by AI in a network. This union enables real-time data gathering, analysis, and automation, bringing more flexibility, efficiency, and productivity.

Networked factories allow manufacturers to quickly adapt to the evolving needs of the marketplace, lower the cost of doing business, and provide higher-quality products with lower downtime and cost.

Example: Rockwell Automation

Best known for its artificial intelligence in manufacturing platforms, Rockwell Automation offers end-to-end real-time visibility into production performance. Its solutions are available in the form of predictive maintenance, process optimization, and automation, making manufacturers more agile and efficient.

To proceed with the intention of integrating AI in manufacturing processes, you should know the fundamental components of your process in summary. By following this approach, you will get to identify your bottlenecks and areas to improve, optimizing your system as well as making it more elaborate and efficient.

Following is the list of principal areas where AI functionality can be integrated without difficulties to automate workflow.

| Key Area | Description | AI Capabilities |

| Predictive Maintenance | Anticipate equipment failures to reduce downtime and optimize maintenance schedules | Predictive Analytics and Machine Learning |

| Quality Control | Use AI-powered visual inspection systems to detect defects and ensure product consistency | AI Computer Vision and Machine Learning |

| Supply Chain Optimization | Predict demand, manage inventory, and streamline logistics for cost efficiency | Supply Chain Analytics, Machine Learning |

| Production Scheduling | Optimize production schedules based on machine availability, material supply, and workforce productivity | IoT for Inventory Management, Predictive Analytics |

| Robotic Automation | Implement AI-powered collaborative robots (cobots) to enhance human-robot collaboration and efficiency. | IoT and Robotics Intersection, Machine Learning |

Implementing AI operations involves a set of strategic methods that can contribute to efficiency, quality, and productivity. What follows is a full guide with steps to ensure taking the appropriate directions to automate manufacturing processes in your business operations:

Walk through your production processes in detail to identify where AI can be used to create substantial value. You can think of AI deployments in predictive maintenance, quality control, and inventory management. This way, you can simply prioritize AI projects based on your areas of need.

For proper functioning, AI systems need accurate and relevant data. The systems in the manufacturing companies should be strong enough to gather and store data from different sources, such as machines and sensors. The gathered data should be appropriate.

structured for deriving meaningful conclusions and making well-informed choices.

Manufacturing firms can choose to collaborate with a preferred app development company to develop high-capacity software solutions that meet particular business needs. The professionals in these firms will make it seamless to integrate with your current systems.

New entrants into the AI manufacturing industry can begin by testing solutions on a small scale via pilot programs in a bid to try out their performance and detect possible operational problems. This can assist beginners in tracking ROI and making the required adjustments before expansion.

Spend time and money on training programs to equip your workforce with the skills to effectively work with AI systems. With a trained workforce, you enhance productivity and accelerate innovation with ease.

AI integration should always be tracked through analytics and user feedback. This enables the redefinition of technology so that it can adapt to changing business requirements.

Read More: Top AI Programming Languages In 2025: What’s Best For Your Next Project?

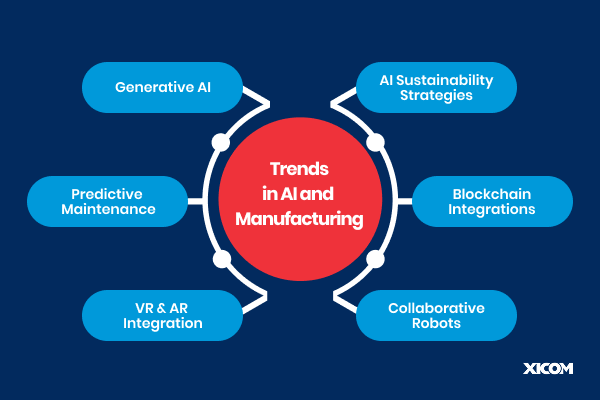

The digital world has been witnessing a major transformation after the introduction of Artificial Intelliegence. Similarly, AI solutions in manufacturing industries are restructuring the way industries operate, offering unmatched improvements in efficiency, product quality, and decision-making. Some of the most significant AI trends witnessed in the manufacturing industry.

Generative AI technologies in manufacturing are utilized to introduce innovation in production and design by creating new ideas and solutions. The application of AI in this way speeds up the product development cycles and introduces innovation in the manufacturing process. Opting for Generative AI development services can help businesses in developing better products.

With predictive maintenance powered by AI, manufacturers are able to scrutinize equipment information to predict breakdowns, lower maintenance expenses and downtime. It takes advantage of the unbeatable ability of advanced learning analytics and machine learning in manufacturing to drive maintenance schedules.

Applications of AR and VR are used mainly in effective training, design review, and real-time process monitoring. They assist in enhancing design accuracy and production monitoring, which can transform operations in a fundamental way.

Intelligent abilities of AI assist in optimizing energy use and reducing carbon footprints. Intelligent energy management systems can take usage patterns into account and suggest modifications to assist manufacturers in achieving sustainability objectives while cutting costs.

Blockchain is expanding its use in manufacturing from supply chain transparency to intellectual property protection. It makes it easy to track confidential designs so they are protected throughout production.

One of the greatest uses of AI in business is the use of Cobots to automate repetitive work and support quality control by leveraging sophisticated sensors. The cobots support human workers by learning through work, changing tasks easily, and enhancing their performance over time.

Read More: Top Generative AI Use Cases and Applications in 2025

There are several changes manufacturing units may face while adopting and integrating AI into their existing workflows. However, with a constant focus on strategic solutions, manufacturers can harness the full potential of AI to optimize operations and drive innovations. The Challenges faced by manufacturing units to integrate AI in their workflows are jotted down below:

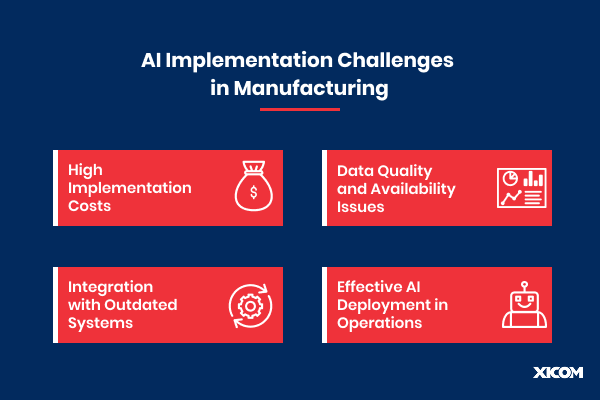

The integration of Artificial Intelligence in manufacturing workflows requires high upfront costs, creating budget challenges for smaller manufacturers.

Solution: Instead of integrating AI into the whole system, businesses can consider implementing AI at different stages. Following this method, companies can gradually integrate AI without a complete system overhaul and within their cost bracket.

AI relies on data, and if the data is locked in disparate systems, it may hinder AI implementation in the manufacturing industry.

Solution: Manufacturing firms are required to enable seamless data sharing by integrating systems and removing barriers to collaboration. Businesses can also implement the data management practices that facilitate the flow of data across the organization.

Many manufacturers who are still dependent on outdated legacy systems may find it challenging to integrate AI technologies. These outdated legacy systems lack the compatibility required to support advanced AI solutions.

Solution: It can be the right choice to utilize integration platforms and API development, enabling easy data sharing and smooth integration of new technologies with existing infrastructure.

Businesses need to understand that AI processes differ for every workflow, and one solution may not scale effectively across different departments or operational processes. This may result in significant challenges when trying to extend AI capabilities across an entire organization.

Solution: It’s always the best choice to hire a developer for implementing customized solutions with the capability of evolving with the business requirement. Businesses can also leverage cloud platforms to enhance scalability, expanding AI applications across all the departments.

With all the stats, use cases, and examples above, it’s clearly visible that AI in the manufacturing industry is a game changer. Its impact on key areas like predictive maintenance, quality control, and supply chain optimization has brought some significant changes. Leading companies like Amazon, BMW, and Ford are leveraging the top-notch capabilities of AI to stay ahead of the competition.

However, to fully utilize the features of AI, manufacturing businesses require professionals to develop and uphold AI-driven applications, making it crucial to hire software developers with industry experience. Partnering with experts can help in achieving customized, scalable, and cost-effective AI solutions for manufacturing.

Here are a few more details to help you navigate the process of integrating AI in manufacturing.

There are many examples of Generative AI use cases in manufacturing, including demand prediction, supply chain management, and customer support.

Yes, AI solutions offer scalability and flexibility, even for manufacturing units. You can get in touch with the software development experts at Xicom and customize the best-suited solutions as per your requirements.

The cost bracket to develop a custom AI for the manufacturing industry can range somewhere between $20,000 to $50,000 and even beyond. However, these charges may vary depending on the type of solution and the capabilities it entails.

Indeed, AI is the future of manufacturing and is expected to reach $16.3 billion by 2027. Leading manufacturing companies have already started adopting the latest technology to enhance efficiency, precision, and adaptability through various capabilities.

With top-tier AI capabilities, businesses can improve product quality and reduce defects by leveraging advanced data analysis, anomaly detection, and predictive maintenance techniques.